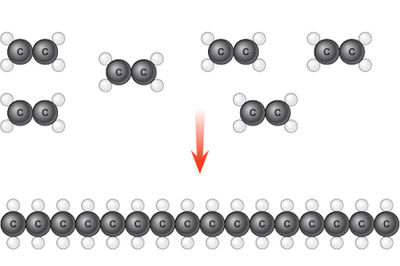

In the development of industrial processes, coupling that understanding By carefully explaining the principles of the reaction,īased on well-designed experimental investigation, this book provides a practical and intuitive approach On understanding and controlling those properties. Properties including polymerisation kinetics and dispersion stability. Chemistry and Technology of Emulsion Polymerisation 1st edition. The drive to develop environmentally benign production methods for polymers has resulted in widespread development and implementation of the emulsion polymerisation technique. Its comparative conciseness (coupled with extensive references) makes it an excellent source for learning the key principles”Įxtended coverage of controlled radical polymerisation in latex productionĮmulsion polymerisation is a complex process, governed by the interplay of both chemical and physical COUPON: RENT Chemistry and Technology of Emulsion Polymerisation 1st edition (9781405121132) and save up to 80 on textbook rentals and 90 on used textbooks. Emulsion polymerisation produces high value polymers in a low cost, environmentally friendly process. “This book will make an excellent graduate level textbook, and a valuable reference book. I would recommend this book toĪnyone beginning a career in industrial polymer chemistry.” “I wish it had been available when I fi rst started using the technique. "synopsis" may belong to another edition of this title. These latest developments are included in the second edition. Controlled radical polymerisation is used in aiding encapsulation of inorganic particles like pigment particles and clay platelets. The second edition of this book includes a new chapter on morphology of latex particles, a rapidly progressing area where modelling the thermodynamic and kinetic aspects of phase separation and morphology has developed into a mature and powerful tool to predict and control morphology of latex particles.Īnother area that is rapidly progressing is the application of controlled radical polymerisation in emulsion polymerization. in VDC emulsion polymerization, 25:723 Free-radical styrene polymerization, general chemistry of, 23:381 Free-radical thermal cracking mechanism. By carefully explaining the principles of the reaction, based on well-designed experimental investigation, the book explains how the principles relate to practical application. An additional indexed section containing. For those working in industry, coupling theory with everyday practice can be difficult. The classes of emulsion polymers are surveyed and the commercial technologies and potential future uses discussed. In turn these polymers were solubilized with various concentrations of ammonium hydroxide and utilised in the surfactant-free emulsion polymerization of butyl methacrylate using persulfate initiators, which also stabilized the polymer particles with observed no coagulation, with solid contents as high as 40%.Chemistry and Technology of Emulsion Polymerisation 2e provides a practical and intuitive explanation of emulsion polymerization, in combination with both conventional and controlled radical polymerization. The vinyl-terminated oligomers were in turn utilised as chain transfer agents, with no further purification, for the formation of diblock copolymers with butyl and methyl methacrylate which constitutes the emulsifier via sulfur-free reversible addition–fragmentation chain transfer polymerisation (SF-RAFT).

#Chemistry and technology of emulsion polymerisation free#

Statistical copolymers of methacrylic acid and methyl methacrylate were synthesised via free radical catalytic chain transfer polymerisation (CCTP) in emulsion to form a hydrophilic emulsifier/surfactant.

0 kommentar(er)

0 kommentar(er)